Blog 2: Gears

- dylanl21

- Nov 20, 2022

- 4 min read

In this page, I will describe:

1. The definition of gear module, pitch circular diameter and the relationship between

gear module, pitch circular diameter and number of teeth.

2. The relationship between gear ratio (speed ratio) and output speed, between

gear ratio and torque for a pair of gears.

3. How I can design a better hand-squeezed fan, including the sketches

4. How my practical team arranged the gears provided in the practical to raise

the water bottle, consisting of:

a. Calculation of the gear ratio (speed ratio)

b. The photo of the actual gear layout.

c. Calculation of the number of revolutions required to rotate the crank handle.

d. The video of the turning of the gears to lift the water bottle.

5. My learning reflection on the gears activities.

1. These are the definition of gear module, pitch circular diameter and the relationship between gear module, pitch circular diameter and number of teeth:

Gear module refers to the size of the gear teeth. The unit for module is mm. The larger a module number, the larger is the size of the teeth. Gears that mesh together have the same module.

Pitch Circular Diameter is the imaginary circle that passes through the contact point between two meshing gears. It represents the diameters of two friction rollers in contact and moves at the same linear velocity.

Relationship between Module (m), No of teeth (z) and Pitch Circular Diameter (PCD):

PCD = m x z

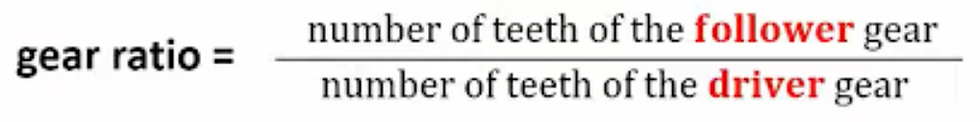

The gear ratio (speed ratio) of a gear train is the ratio of the angular speed of the input gear to the angular speed of the output gear. It can be calculated using a ratio of the teeth, radius, diameter or circumference of the gears.

Torque is a measure of the force that can cause an object to rotate about an axis. It is calculated by multiplying the magnitude of the force with the distance to the axis of rotation.

2. Below is the relationship between gear ratio (speed ratio) and output speed for a pair of gears.

The higher the gear ratio, the lower the output speed.

Below is the relationship between gear ratio and torque for a pair of gears.

The higher the gear ratio, the higher the torque.

An activity of the practical required my group to assemble a hand-powered fan. Here is a video of the fan in action

This is a sketch of the internal components of the fan by my group.

Here are the calculations my group did to find the speed ratio of the fan.

3. Below are the proposed design to make the hand-squeezed fan better:

A better hand-squeezed fan should be one that would rotate faster to blow more air at the user. The gears should be arranged so that the gear ratio would be as low as possible to make the follower gear as fast as possible.

Another issue is when the arm of the handle goes further in and the handle is closer to the opening, it would get stuck and the arm would have difficulty moving up or down. To solve this issue, the handle could be replaced with a flywheel handle lever or the gears and inner surface of the frame be sanded smoother to reduce friction.

4. Below are the description on how my practical team arranged the gears provided in the practical to raise the water bottle.

My group started off by arranging the gears given by the number of teeth they had. This would help to figure out the arrangement for the gear ratio needed.

My group came up with this sketch. You may notice some differences between the sketch and the photo of the actual arrangement below. This is because the sketch has some mistakes :V

a. Calculation of the gear ratio (speed ratio).

b. The photo of the actual gear layout.

c. Calculation of the number of revolutions required to rotate the crank handle.

d. The video of the turning of the gears to lift the water bottle.

5. My learning reflection on the gears activities.

In secondary school, I was in robotics 🤖 for 1 year. In robotics, they used Lego parts. What I'm trying to say is that I had prior experience with gears, Lego gears. During my time in that CCA, I roughly knew how gears work from observing how different types interact with each other, especially when trying to arrange the gears for acceleration. One project I saw was using gears and motors to accelerate Lego wheels that would spin fast to shoot a ping pong ball 🏓. I thought that project was cool and it made me interested in gears. However, I did not learn the theory and math behind gears. From the package, I learnt about gear ratios, idler and compound gears, and the math behind a gear train. However, I was unfortunate enough to be sick with COVID so I could not attend the practical. I could still learn from the work my group member's had done for each activity and reinforce my current knowledge. For example, I could look at the picture of the gear train my group had done to carry the water bottle and compare the calculations with the picture. I would like to try activities with screw gears and internal gears as they are more unique, and it would help me expand my view on the practical use of gears. I hope to put my new knowledge of gears to good use in my CPDD CA2 and my capstone project in the future.

Comments